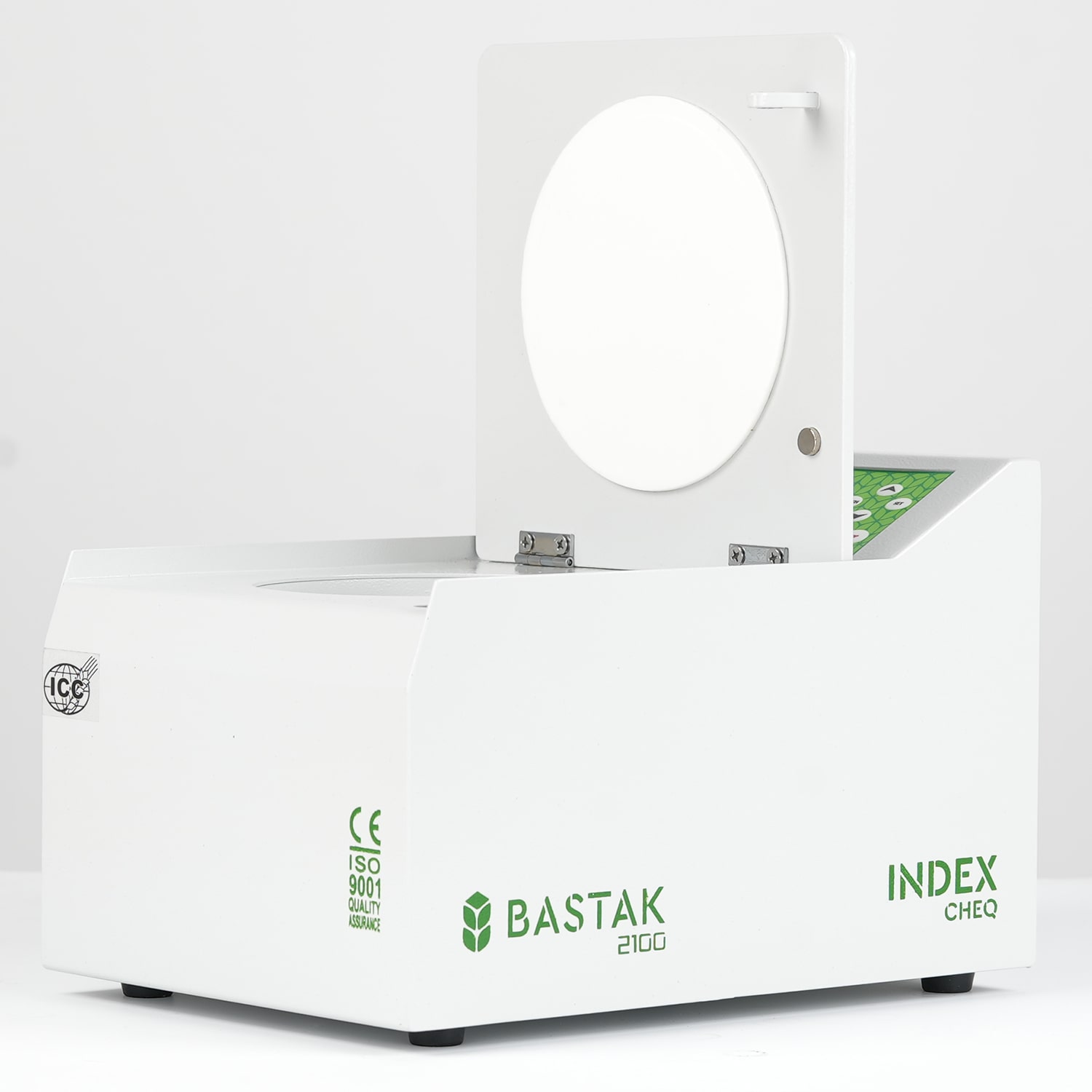

Bastak Centrifuge Cheq 2100 – Advanced Gluten Index Analyzer for Flour Quality Assessment

The Bastak Centrifuge Cheq 2100 is a state-of-the-art gluten index analyzer designed to accurately determine the quality and quantity of wet gluten in various flour types, including wheat flour, whole wheat flour, semolina, bulgur, vital gluten, and vermicelli. This gluten quality testing equipment is essential for flour mills, bakeries, and quality control laboratories aiming to ensure product consistency and compliance with international standards.

Operating at 6000 rpm, the device adheres to the ICC world standard, providing high repeatability and accuracy in test results. Its microprocessor-controlled system, coupled with membrane technology, allows for simultaneous analysis of two samples within one minute, enhancing efficiency in high-throughput environments. The LCD graphic screen displays critical information such as company name, date, time, ambient temperature, device status, operating cycle, and remaining test time.

Safety features include a cover with built-in sensors that prevent the device from operating unless securely closed, complying with CE standards. Post-test, the device automatically locks the cover, applies an automatic brake system, emits an audible alert, and unlocks the cover, ensuring user safety and convenience.

The Bastak Centrifuge Cheq 2100‘s working principle involves centrifuging wet gluten at a constant speed, where a portion of the sample passes through a special sieve. The ratio of gluten that does not pass through the sieve to the total gluten amount provides valuable information about gluten quality.

This flour quality control centrifuge is compatible with gluten washing and dry gluten devices, making it a versatile addition to any laboratory setup. Its ergonomic structure and user-friendly interface make it an indispensable tool for professionals committed to maintaining high standards in grain quality assessment.

With this device, the amount and quality of wet gluten obtained from flour, whole wheat flour, semolina, bulgur, vital gluten and vermicelli are determined at world standards, and a unique analysis experience is offered to the user. Measurement of gluten amount, dry gluten and gluten index values in flour and semolina used in bread, pasta, biscuits and pasta is very important in measuring the final product volume, determining the baking and cooking quality and ensuring that the product conforms to world standards.

ADVANTAGES

– Microprocessor controlled

– Membrane Technology

– Ergonomic structure

– Tracking of company name, date, time, ambient temperature, work done by the device (ready, testing, stop…etc), device operating cycle and remaining test time with LCD graphic screen

– Working at 6000 rpm, which is the ICC world standard

– Gluten index value determination of 2 samples at the same time in 1 minute

– Thanks to the safety sensors on the cover in accordance with CE standards, the device does not start the test before the cover is closed.

After the device starts the test, the cover is locked automatically, and after the test period, the device stops with the automatic brake system, gives an audible warning and the cover is unlocked automatically.

Gluten quality is a factor that directly affects the cooking/baking quality of the products. It is essential to use the Gluten Q-System for real gluten quality and quantity.

Working Principle

As a result of the centrifugation of wet gluten at a constant speed, a part of the sample passes through the special sieve. The ratio of the amount of gluten that does not pass the sieve to the total amount of gluten gives information about the quality of gluten.

There are no reviews yet.