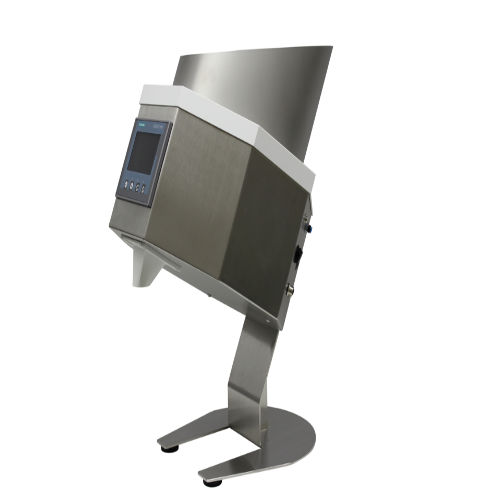

Counting and Filling Machine:

This professional GMP-compliant counting and filling machine is engineered to accurately and efficiently handle tablets, capsules, dragees, and other molded pharmaceutical products. Built to meet IP65 protection class standards, it is ideal for daily use in pharmaceutical production, pharmacies, and contract manufacturing environments.

Compact, Reliable, and Industry-Ready

Designed as a compact tabletop unit, this machine delivers industrial-level performance in a space-saving format. It ensures nearly 100% counting accuracy, reducing product loss and optimizing the production process. Unlike traditional filling based on weight, which can lead to inconsistencies, this unit guarantees precision filling by count.

Key Applications

-

Filling Operations: Set the number of containers and the quantity per container with full flexibility.

-

Incoming Goods Inspection: Use the integrated inventory function for 100% counting of incoming batches.

-

Batch Control & Quality Assurance: Reliable and repeatable results for consistent output.

Intuitive Operation

The device is controlled via a user-friendly touchscreen interface, making it easy to operate, even in high-speed production settings. Settings can be quickly adjusted for different product types and production needs.

Easy Maintenance and Cleaning

A built-in cleaning unit connects to a compressed air system (clean, dry, oil-free air at 1–5 bar). This optional feature is especially useful when processing dusty products. All components are built using stainless steel and aluminium with DURIN-COAT®, while the format discs are made of PET, ensuring compliance with FDA standards and long-term durability.

Maximum Flexibility with Format Discs

Whether you’re processing tablets, capsules, or pills, the machine offers full flexibility with easily interchangeable format discs. Standard discs are readily available from stock. Custom solutions for unique product shapes can typically be produced at no additional cost.

Optional Fully Automatic Filling Station

Enhance efficiency with the automatic filling station module, capable of filling up to 32 containers in one cycle, depending on bottle or container size. This module connects seamlessly to the machine via the I/O port and features height-adjustable feet to accommodate various container heights.

There are no reviews yet.