Control System Overview

Display & Interface

-

5.4” LCD Touch Screen Display:

-

Simultaneously shows all main parameters including cold trap temperature, vacuum degree, sample temperature, and shelf temperature.

-

-

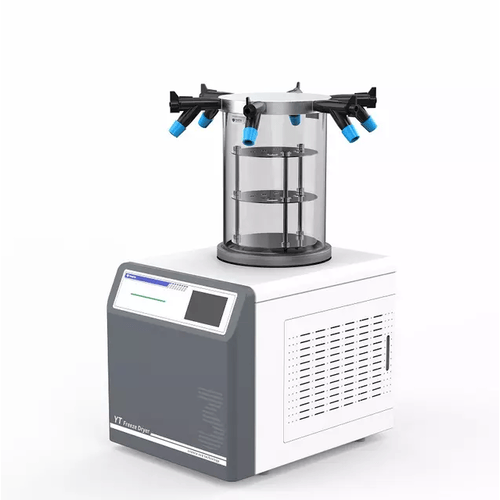

Schematic Diagram:

-

Graphic display of the equipment’s operating components, allowing users to view the working status of each part.

-

Pre-Cooling & Preheating Functions

-

Cold Trap Pre-Cooling & Vacuum Pump Preheating:

-

User-set timing options within the system ensure optimal preparation for freeze-drying operations.

-

-

Status Indication:

-

Displays the current running status—normal or abnormal—using numerical color indicators.

-

Built-In Data & Relationship Display

-

Saturated Vapor Pressure & Temperature Table:

-

Directly displays the corresponding relationship between saturated vapor pressure and temperature for informed process control.

-

Key Operational Features

-

One-Key Operation:

-

Extremely simple to operate; no special professional training required.

-

-

Safety Protections:

-

Thermal electromagnetic over-current and short-circuit protection enhance safe and stable equipment operation.

-

-

Maintenance Reminders:

-

Actively reminds users when equipment maintenance or vacuum pump lubricating oil replacement is due.

-

-

Ambient Temperature Monitoring:

-

Automatically triggers an alarm if the ambient temperature exceeds safe limits.

-

-

Optional Enhancements:

-

Supports an optional eutectic point detection device and endpoint-judgment detection system to make freeze-drying processes more scientific.

-

There are no reviews yet.