Description

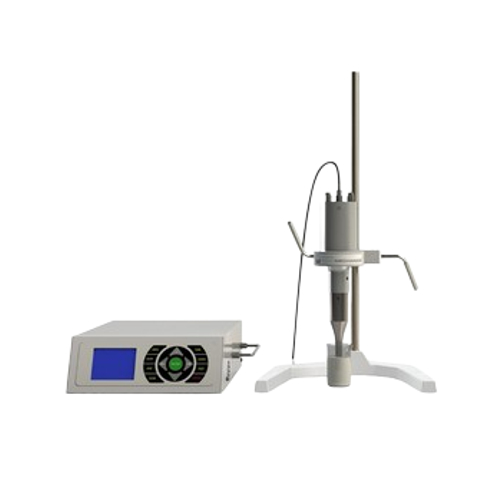

The LSP-600 ultrasonic liquid processor comes standard with: 600 W ultrasonic generator, air-cooled transducer, full-wave Barbell Horn®, medium-duty support stand, spanner wrench set, and noise reduction ear muffs. Optional items include: flow-through reactor chamber (flow cell), magnetic stirrer with hotplate, water chiller, air blower, 2 L process vessel, peristaltic pump, beaker, NanoStabilizers®, and filters.

Key Features

-

Patented Barbell Horn® Technology: Delivers high ultrasonic amplitudes with a wide range of amplitude control, ensuring efficient processing across various applications.

-

Dual Configuration Modes: Supports both batch and flow-through configurations, accommodating liquid volumes ranging from 15 mL to 2 L, thus offering flexibility for different processing needs.

-

State-of-the-Art Components: Equipped with a 600 W ultrasonic generator, air-cooled piezoelectric transducer, and full-wave Barbell Horn®, all designed for optimal performance and reliability.

-

Comprehensive Accessory Suite: Includes optional accessories such as a flow-through reactor chamber with cooling jacket, magnetic stirrer with hotplate, peristaltic pump, and more, allowing for customized setups tailored to specific applications.

-

User-Friendly Design: Features intuitive controls with real-time monitoring of output power and frequency, fine amplitude adjustment (20–100%), and automatic power adjustment, ensuring ease of operation.

Applications

The LSP-600 ultrasonic liquid processor is adept at handling a wide range of applications, including:

-

Nanoparticle dispersion

-

Emulsification

-

Cell disruption

-

Degassing

-

Deagglomeration

-

Extraction processes

Its capability to process liquids with high solids content and varying viscosities makes it suitable for diverse industries such as pharmaceuticals, biotechnology, food and beverage, and materials science.

There are no reviews yet.