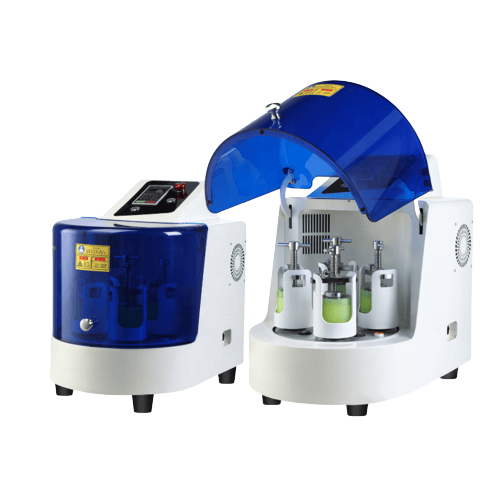

Mini Planetary Ball Mill Laboratory Oil seal silent invention patent, which reduces noise by more than 50% compared to ordinary planetary mills in the market and extends service life by 2 times. Compact in appearance, saves laboratory space, and can be directly placed on the desktop for work.

Technical Specification of Mini Planetary Ball Mill Laboratory

| Application | Pulverizing, Mixing, Homogenizing, Colloidal Grinding, Mechanical Alloying, Mechanical Chemistry | |

| Field of Application | New Energy, Geology/Metallurgy, Glass/Ceramics, Engineering/Electronics, Building Materials, Environment/Recycling, Agriculture, Chemistry, Biology, etc |

|

| Sample Characteristics | Soft, Hard, Brittle, Fibrous – dry or wet | |

| Pulverization Principle | Impact, Friction | |

| Material Feed Size | < 5 mm, soil < 10 mm | |

| Final Fineness | For colloidal milling, output < 0.1 µm | |

| Grinding Method | Dry, wet, vacuum, atmosphere-protected grinding possible | |

| Material of Grinding Jar | Stainless steel, tungsten carbide, zirconia, alumina, silicon carbide, silicon nitride, polyurethane, nylon, PTFE, onyx | |

| Ratio Setting | 1::2 | |

| Model | BQM-0.4L | BQM-1L |

| Grinding Jar Volume | 50-100ml | 50-250ml |

| Vacuum Jar Volume | 50ml | 50-100ml |

| Revolution Speed | 5-450r/min | |

| Rotation Speed | 10-900r/min | |

| Power | 0.55KW | |

| Voltage & Frequency | Single Phase,220V/50Hz | |

| Dimensions (WxDxH) | 540 x 400 x 570 mm | |

| Weight | 55kg | 57kg |

There are no reviews yet.